Details Display

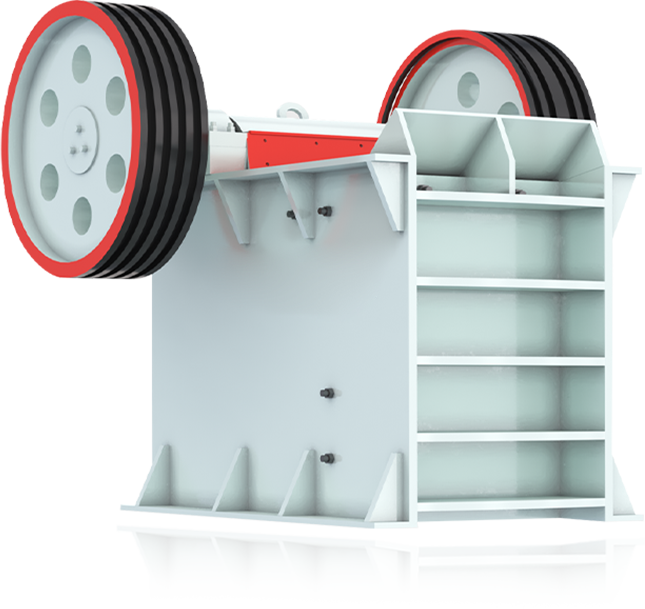

Jaw crusher structure:

The working part of the jaw crusher consists of two jaw plates, one is the fixed jaw plate, which is fixed on the front wall of the machine body, and the other is the movable jaw plate, which is fixed on the eccentric shaft, tilted in position, and forms a crushing chamber with the fixed jaw plate that is larger at the top and smaller at the bottom. The motor drives the belt and pulley, and the movable jaw plate moves up and down through an eccentric shaft. When the movable jaw plate rises, the angle between the elbow plate and the movable jaw plate increases, thereby pushing the movable jaw plate closer to the fixed jaw plate. At this time, the material is crushed by multiple forces such as compression, rubbing, and rolling. When the movable jaw descends, the angle between the elbow plate and the movable jaw plate decreases, and the distance between the movable jaw plate and the fixed jaw plate increases under the action of the pull rod and spring. At this time, the crushed material is discharged from the discharge port of the crushing chamber. With the continuous operation of the eccentric shaft, the movable jaw plate undergoes periodic reciprocating motion, and the material entering the crushing chamber is continuously crushed and discharged, achieving continuous production.

Applicable materials:

Limestone, river pebbles, quartz, iron ore, basalt, copper ore, cement clinker, coal gangue, gold ore, construction waste, potassium feldspar, granite, calcite, marble, magnetite……

Application areas:

Widely used in sand and gravel yards, mining, coal mining, concrete mixing plants, dry powder mortar, power plant desulfurization, quartz sand, etc. Widely used in various industrial sectors such as metallurgy, mining, chemical industry, cement, construction, refractory materials, and ceramics for medium and fine crushing of various medium hard ores and rocks.

Online consultation

Related suggestion

Get Free Quotes

NEED TO CHAT?

Telephone: +86-138 **** 7385

E-mail: heaven@****.com / ****@163.com

Add: NO.1 **** WestDistrict, Zhongshan, Guangdong, China

Get Free Quotes